Custom Ear Molds

Columbine Hearing Care provides custom ear molds in Littleton, CO.

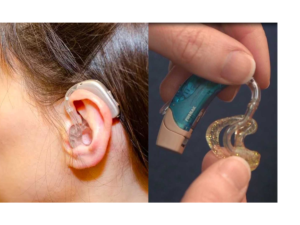

Custom ear molds, also known as custom earpieces, are specially crafted devices that fit snugly inside a person’s ear.

They are individually designed and manufactured to match the unique shape and contours of an individual’s ear canal. Custom ear molds are commonly used for a variety of purposes, including:

Hearing Protection

Custom ear molds can be used as hearing protection devices to reduce exposure to loud noises. They are often used by musicians, construction workers, and individuals exposed to noisy environments.

Custom ear molds can be used as hearing protection devices to reduce exposure to loud noises. They are often used by musicians, construction workers, and individuals exposed to noisy environments.Hearing Aids

Custom ear molds are frequently used in conjunction with hearing aids. They provide a comfortable and secure fit for the hearing aid device, ensuring optimal sound transmission and reducing feedback or whistling.

Custom ear molds are frequently used in conjunction with hearing aids. They provide a comfortable and secure fit for the hearing aid device, ensuring optimal sound transmission and reducing feedback or whistling.In-ear Monitors (IEMs)

Musicians and audio professionals often use custom ear molds for in-ear monitors. These molds provide a precise fit, sealing the ear canal to deliver accurate sound reproduction while blocking out external noise.

Musicians and audio professionals often use custom ear molds for in-ear monitors. These molds provide a precise fit, sealing the ear canal to deliver accurate sound reproduction while blocking out external noise.Communication Devices

Custom ear molds can be used with communication devices such as two-way radios or Bluetooth headsets. They provide better sound quality, noise isolation, and improved comfort compared to generic earpieces.

Custom ear molds can be used with communication devices such as two-way radios or Bluetooth headsets. They provide better sound quality, noise isolation, and improved comfort compared to generic earpieces.Water Protection

Custom ear molds that float are often used for swimming or bathing by people who don’t like the feeling of water in their ears, or who cannot get water in their ears for medical reasons (such as ear infections or tubes in the ears).

Custom ear molds that float are often used for swimming or bathing by people who don’t like the feeling of water in their ears, or who cannot get water in their ears for medical reasons (such as ear infections or tubes in the ears).The process of obtaining custom ear molds typically involves a visit to an audiologist or hearing instrument specialist. During the appointment, a soft, putty-like material is placed in the ear to create a mold. This mold is then used as a basis to manufacture the custom earpiece, which is usually made of a medical-grade silicone material.

Custom ear molds offer several advantages over generic earpieces or one-size-fits-all options. They provide a more secure and comfortable fit, improved sound quality, and better noise isolation. However, they require a professional fitting and are generally more expensive than off-the-shelf alternatives.

Columbine Hearing Care has audiologists in Littleton, CO, who can provide excellent hearing care and hearing aid services.

Types of Custom Ear Mold Materials

There are many types of custom ear molds, each with its own unique benefits and features.

Below are the three most common types of custom ear molds:

These custom ear molds are made from a pliable material that can be customized to fit the unique shape of the ear canal. They are comfortable, lightweight, and affordable. Vinyl ear molds are recommended for mild to moderate hearing loss and can be used for a variety of settings – for communication, listening to music, or hearing protection.

Silicone ear molds are made from a soft and flexible material that makes them really comfortable to wear. They are hypoallergenic, durable, and long-lasting, making them ideal for wearers who are looking for a high level of hearing protection or who need to use ear molds often. This type of ear mold delivers a high level of noise reduction, making them ideal in noisy environments.

Acrylic ear molds are made from a tough, durable material and are designed to provide a high level of hearing protection. They are very versatile and can accommodate a range of hearing aid styles and communication devices.

Frequently Asked Questions

How are custom ear molds made?

Custom ear molds are made by taking an impression of the wearer’s ear canal. First, the audiologist will need to check the ear to ensure that there are no obstructions such as dirt, debris, wax, or foreign objects.

Once the area is clear from any obstruction, a cotton or foam block will be placed into the ear canal and then a soft silicone material will be inserted into the ear canal and the bowl of the ear. It typically takes about 2 minutes for the material to harden. You may be asked to open and close your mouth or hold a small styrofoam block in your mouth during this hardening process. Once the material has hardened, the audiologist will massage the ear mold impression out of your ear.

The impression will then be used as a model to create the custom ear mold. During the finishing process, it can be customized to filter out specific frequencies and address the wearer’s individual hearing requirements.

How often should custom ear molds be replaced or remade?

The frequency of replacing or remaking custom ear molds can vary depending on several factors, including individual circumstances and usage. Here are some general considerations:

Wear and Tear: Over time, custom ear molds can experience wear and tear, especially if they are used frequently or exposed to harsh conditions. The lifespan of the ear molds can be affected by factors such as the quality of the materials used and the level of maintenance and care.

Changes in Ear Anatomy: The shape of the ear canal can change over time due to various factors, such as aging, weight fluctuations, or medical conditions. If there are significant changes in the ear anatomy, it may be necessary to have the ear molds remade to ensure a proper fit and optimal performance.

Hearing Aid Updates: If you use custom ear molds with hearing aids, changes or upgrades to your hearing aids may require adjustments or remaking of the ear molds to accommodate the new devices.

As a general guideline, it is recommended to have custom ear molds evaluated by a professional periodically, such as during routine hearing check-ups. They can assess the condition and fit of the ear molds and provide recommendations on whether replacements or remakes are necessary.

It’s important to follow the guidance of your audiologist regarding the appropriate timing for replacement or remaking based on your specific situation.